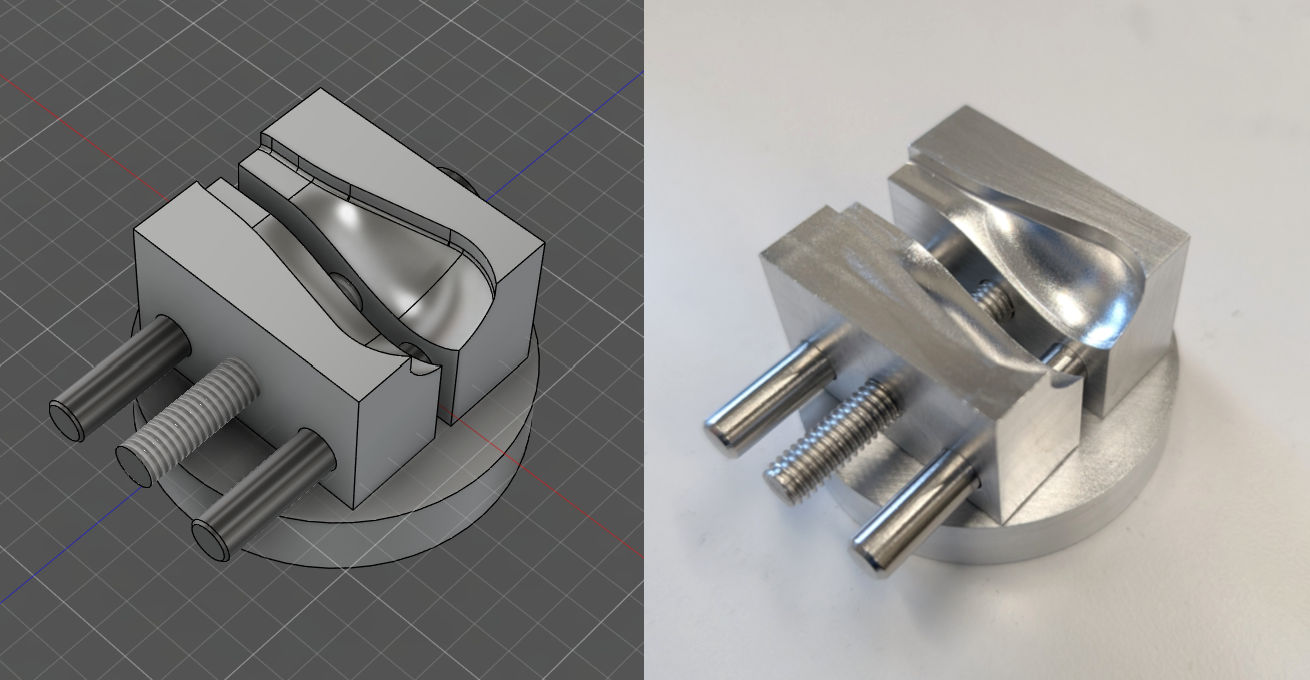

Custom clamp for SEM: testing cheap CNC services

At work, we often need to analyze complex geometries using a JEOL scanning electron microscope. A common task involves examining the flat portion of a zip puller, which is the signature object of the company I currently work for. However, the clamps provided by the SEM manufacturer are not suitable for curved or intricate shapes.

To address this, I decided to design a custom clamp and find the most cost-effective way to manufacture it. I chose JLC’s CNC service because I had previously been impressed by the quality and price of their 3D printing services. Since the clamp needed to be conductive, I opted for aluminum 6061 alloy, the same material used for the existing clamps and sample holders.

I designed the clamp in Autodesk Fusion 360, created detailed PDF drawings for the threading, and uploaded everything, including the STEP file, to JLC’s CNC service. I sourced stainless steel rods, set screws, and the main screw from AliExpress. The total cost for the clamp was €85. While it might be possible to reduce costs using metal 3D printing, given the curved surfaces that require multiple machining passes, I was impressed with the quality of the CNC-machined aluminum and wanted to try a different service.

I am very satisfied with the final product and plan to use this approach again in the future. This was my first custom CNC-machined part, and I was thrilled to see that everything fit together perfectly on the first try!